Special Solutions

Your companion on the journey to the new technologies

Technologies also have an expiry date. In 2015 Siemens will have discontinued the products of the SIMATIC S5 series. Deliveries of spare parts or compatible technologies will no longer be possible.

Specialists in the field of S5 products will also be a rarity. So that you can continue to meet the challenges of the growing market, we support you in modernizing your technical systems. A migration is the conversion of software and hardware to a new system. Depending on your needs, your functionalities are retained and, if necessary, optimizations are carried out.

Depending on your planning and your existing system control, such a migration can also be carried out step by step. Your way to the new technology:

Your advantages:

- Improvement in production capacity

- Increase in productivity and product quality

- Availability of spare parts and experts

- Make work easier for your own maintenance staff

- Compliance with current standards and regulations

- Analysis of your existing system

- Define your goal

- Conversion of the controls with local and decentralized I/Os

- Exchange of visualization systems and computing technology

- Customization of the network type and its associated components

- Translation of the existing software into the current system language

- Performing optimizations

- Training of operators in the new technology

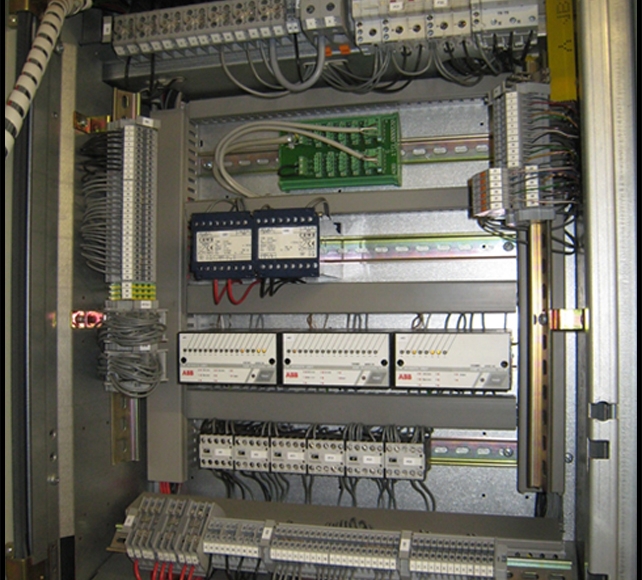

Retrofit of the motor management modules of various ABB MNS switchgear

Project description

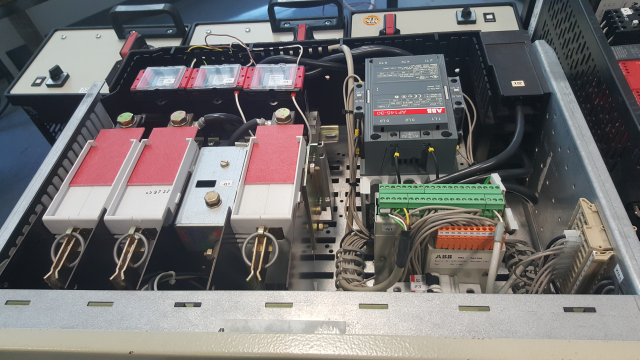

Migration of the ABB INSUM motor modules for various inserts of the ABB MNS switchgear.

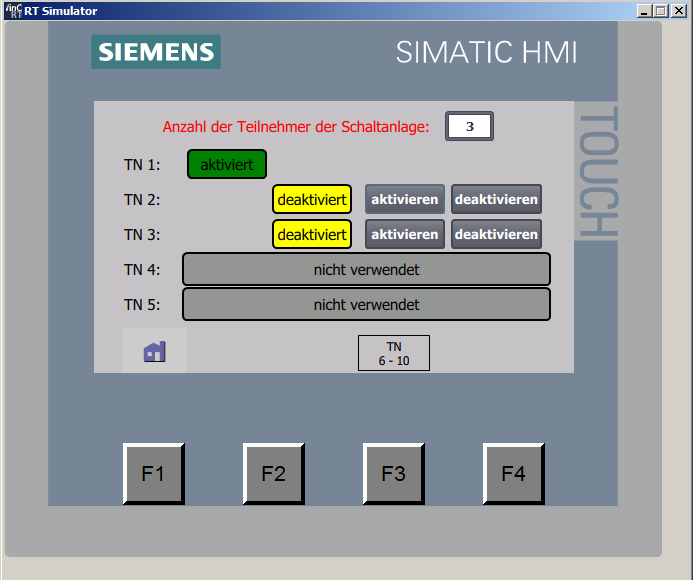

Between 2 and 22 plug-in units in sizes 1A (MO302) – 250A (MO511) from the ABB MNS series were converted per switchgear. Special applications, such as reversing operation, with an emergency stop and double drive, also came into play. The existing BA501 was converted to a solution with a Siemens PLC control for the control and administration of the modules. The software stored in the PLC works intuitively for all variants. This means that there is only one software for all switchgear sizes and variants.

Project Data

- Design of the required material.

- Collection of the corresponding reserve modules from the client. If this is not possible because there are not enough plug-in units in reserve, the conversion is carried out on site. In this case, the conversion should ideally be carried out during downtime. Then the inserts are taken to the IBAR headquarters for conversion.

- Testing of the finished inserts on the IBAR test bench. This was specially created for this purpose with a separate test PLC.

- Inserting the converted slots and putting them into operation.

- Documentation according to the guidelines of the client with red revision of the circuit manuals.

- Creation of a manual for system operation

Software used

- Siemens SIMATIC STEP 7 Professional V13 SP1

- Siemens SIMATIC WinCC Advanced V13 SP1

Hardware used

- Siemens SIMATIC S7-IM CPU

- Siemens SIMATIC HMI, KTP400, BASIC PANEL

- Siemens SIMOCODE PRO V including current measurement in various sizes

Retrofit of the automatic switching of various ABB MNS switchgear

Project description

Migration of the ABB Procontic CS31 control for the automatic switching of the ABB MNS switchgear.

Two associated switchgear from the ABB MNS series were migrated. In particular, the programmable logic controllers of type ABB CS31 responsible for monitoring the switching.

Software used

- ABB AC31

- Siemens SIMATIC STEP 7 Professional V13 SP1

- Siemens SIMATIC WinCC Advanced V13 SP1

Hardware used

- Siemens SIMATIC S7-1200, COMPACT CPU

- Siemens SIMATIC ET 200SP (remote peripherals in the switchgear panels)

- Siemens SIMATIC HMI, KTP700, BASIC PANEL

Project Data

- Reading out the project planning (programming) of the old ABB CS31 controller and converting it to Siemens S7.

- Reconfiguration of the screens and messages for the panel to be used.

- Retrofitting the old ABB CS31 controls including the old system bus to the ABB periphery.

- Installation of new Siemens S7-1200 controllers including remote peripherals and 7″ panels in the switchgear instead of the ABB controllers.

- Rewiring of the bus line (PROFINET) between the relevant switchgear to connect the PLC controls and within this to connect the remote peripherals.

- Retrofit of cross communication between the controllers for data exchange and detection of the switchover request.

- Documentation according to the guidelines of the client with red revision of the circuit manuals.

- Creation of a manual for system operation

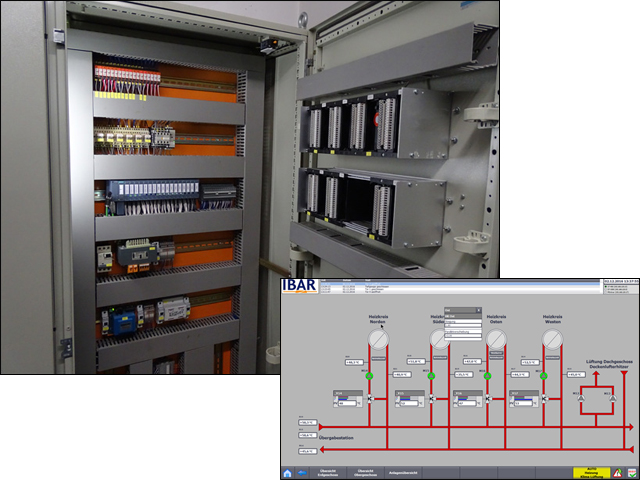

Retrofit of the building management system DDC3000 (Kieback & Peter) to SIMATIC S7

Project Description:

In the new main building of IBAR Systemtechnik, an old building control system from Kieback & Peter (DDC3000) installed. Due to the poor documentation and the limited maintenance options (here only possible by Kieback & Peter), it was decided to replace the system with a Siemens SIMATIC S7 controller.

The DDC3000 system was designed in such a way that all substations communicated via the system’s own buses and were connected to the GLT visualization system Neutrino via a central interface.

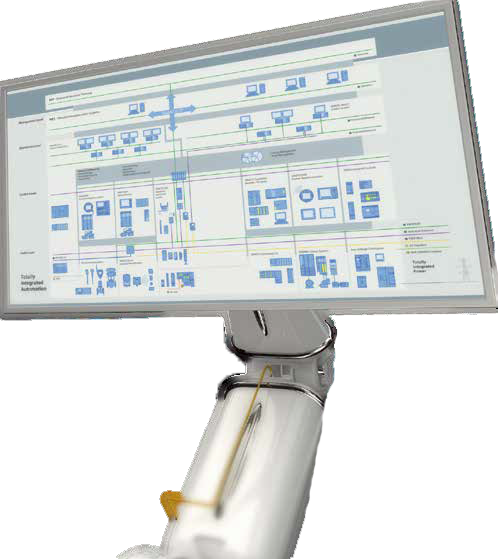

The overall concept of the old system was analyzed and restructured. The Kieback & The M, K and Z buses used by Peter System have been replaced by the industrial bus Profinet. An S7-1500 was used as the central control system. All subsystems were connected to the S7-1500 via ET200SP and Profinet-IM.

The new building management system is now visualized via a WinCC client. The images of the existing system were largely retained. The new faceplates from TIA V14 were used for operation.